Accurate projection of laser outlines for positioning, assembly and verification

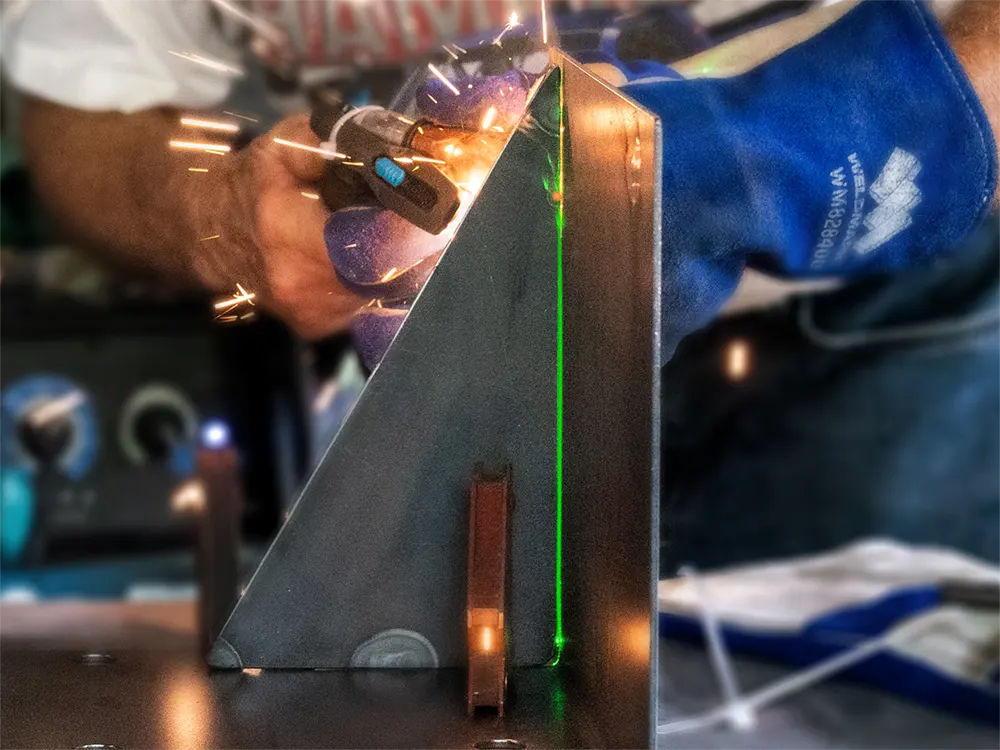

Using physical templates and shop drawings for building construction is cumbersome, time-consuming and prone to error. But FARO Tracer Laser Projectors project the original CAD or other model — the single source of truth — directly onto building materials, ensuring quick and accurate positioning, assembly and verification. Manufacturers have relied on these tools for more than 20 years. Now, we’re bringing these technical advantages to the construction and prefabrication industries, along with our deep metrology expertise and our exclusive capability to integrate the projectors into construction workflows.

- Overview

Build with Confidence: Use Tracer Laser Projectors to bring a new level of assurance to operations in the prefab factory or even in the field.

Minimize Scrap: The accuracy of laser outlines saves money and keeps projects “green.”

Save Time: The efficiencies gained can save weeks on every prefabrication project.

Reduce Labor: Using projected laser outlines requires far less work than physical templates, resulting in significant cost savings.

Enable Business Growth: Tracer Laser Projectors help you finish more projects in less time.

Keep Building Owners and Tenants Happy: The high-quality construction process results in a building everyone can feel good about.

For Projection and Advanced Verification

For Projection and Visual Verification

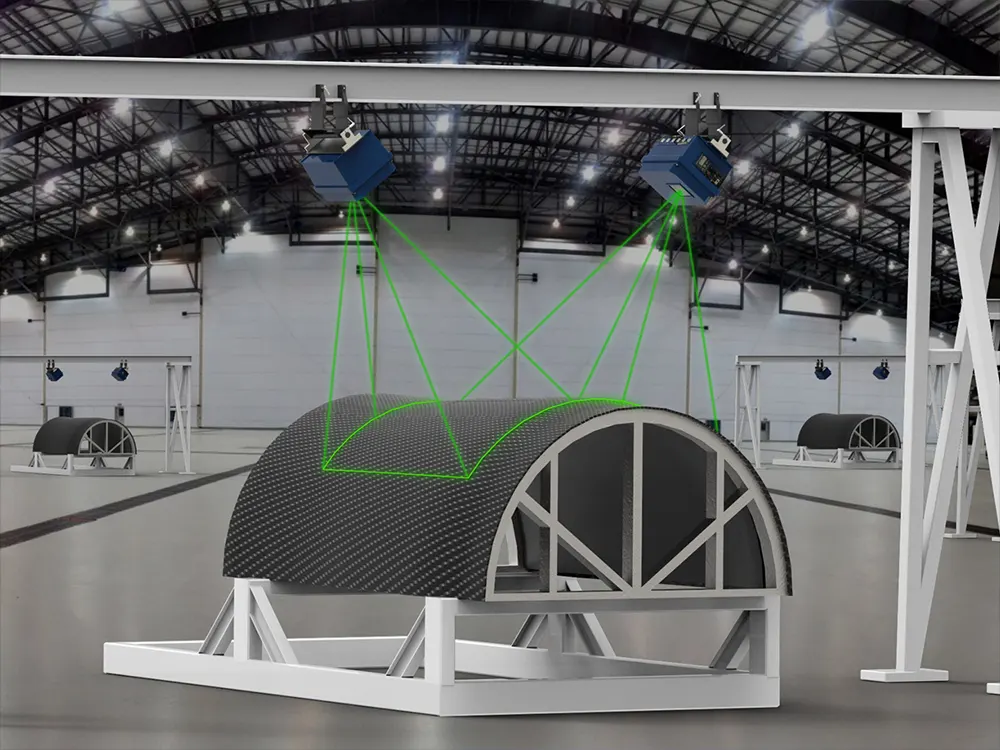

3D CAD-based Virtual Templating: Use virtual templating in a variety of manufacturing applications.

Exceptional Projection Accuracy: Project with accuracy of 0.25 mm (0.010 in.) at 4.6 m (15 ft.).

Workflow Automation: Use: Tracer Laser Projectors with BuildIT Metrology Software and BuildIT Projector Software to automate workflow.

Long-range Projection: Achieve accurate, variable and long-range projection (up to 15.2 m).

Advanced Trajectory Control (ATC): Ensure fast projection, superior dynamic accuracy and rapid refresh with minimized flicker.

Multi-projector Array: Operate several laser projectors from a single workstation; ideal for large assemblies and space-constrained areas.

Rugged, Reliable Design: Work with the protection of the device’s dust-sealed industrial enclosure and active thermal management.

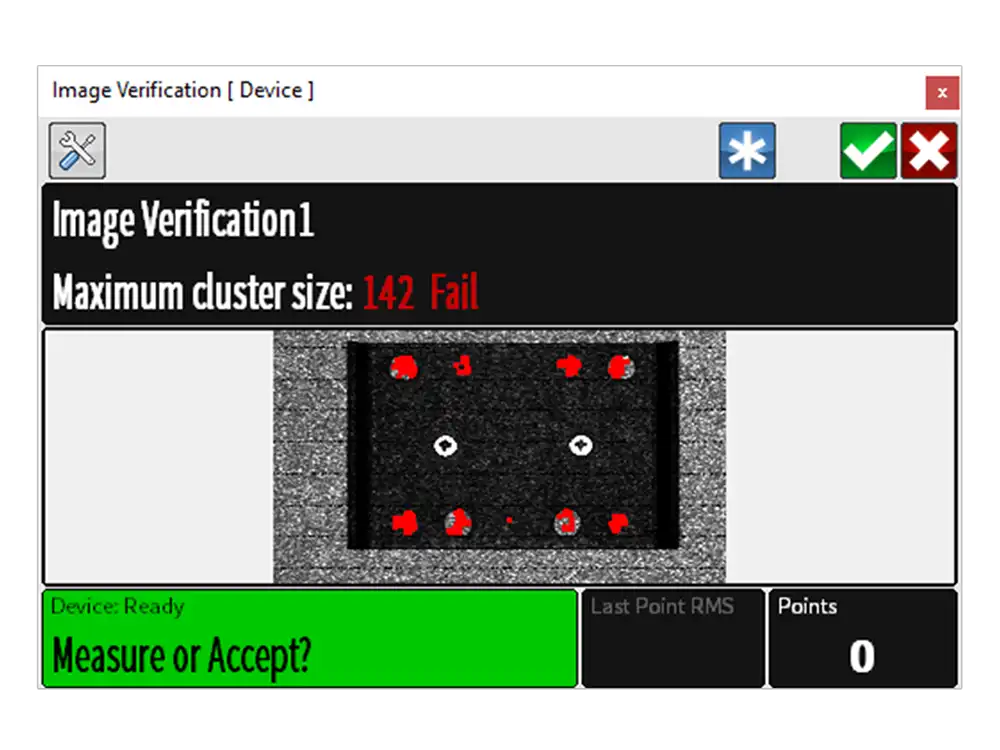

In-process Verification: Verify work at quality-assurance checkpoints during and after critical assembly processes.

Feature-based (Targetless) Alignment: Align projections to checkerboard targets or compare known features of an object to the CAD model for an alignment process that’s faster and easier, eliminating the time and effort of setting up targets for projection.

Foreign Object and Debris (FOD) Detection: Gain even greater quality assurance.